Guess the Contact Angle: IPA Wiped Composite Material

This 'Guess the Contact Angle' video is the first of our next series of videos focusing on how contact angle changes when a composite surface is cleaned or treated in various ways. The contact angle featured in this demo is formed by a water droplet deposited using the handheld Surface Analyst on...

Read

Topics:

Posts by Topic

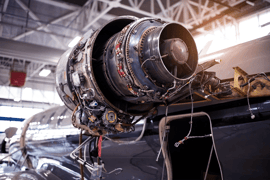

A Great Idea to Help Save the Aerospace Industry

2020 is a year that will live in infamy for many industries. We haven't even seen the full effect of Covid-19 on economies, which inserts a heap of uncertainty into decision-making for manufacturers. But one thing is for sure: we're not going to get back to business as usual anytime soon. The ...

Read

Topics:

Everything Breaks: What Reliability Means for Adhesively Bonded Products

The seemingly easy and obvious answer to the question implied in the title of this article is: reliability means no failures whatsoever forever and ever, amen. Sadly, it’s not quite so simple.

Read

Topics:

How to Bond Fiber Reinforced Plastics for Harsh Environments

Many manufacturers have a dual performance concern when their products are out there in the world being used in whatever capacity they were designed for. These parallel interests are: how to maintain the appearance and how to guarantee structural integrity through common usage of the products.

Read

Topics:

Study Proves the Surface Analyst is Dependable for Process Control

One of our favorite services we provide to manufacturers is to help optimize surface preparation techniques for their particular materials and products. It’s our specialty and one of our biggest passions. We feel so strongly about it because we know that if you, as a manufacturer, are able to...

Read

Topics:

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. For aircraft OEMs, one of the most crucial aesthetic operations is the topcoat of paint, although...

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Surface Preparation for Primer Coating of Composites in Aerospace Applications

A lot goes into painting an aircraft. This massive, multi-stage process begins long before that final, shiny topcoat you see on the wings and tail is applied. The components are molded, then they’re prepared (which is often a multi-step process in-and-of-itself), then they’re assembled, then there...

Read

Topics:

Surface Treatment of Thermoplastics for Aerospace Components

The Aerospace and Defense Industry is experiencing a market boom right now. Investments in the aerospace industry are an increasingly significant part of the world economy. Last year, almost $1 trillion was spent worldwide, with about $400 billion spent directly on aircraft and space systems...

Read

Topics:

Automotive Series: Surface Preparation of Composite Surfaces

Building a More Fuel-Efficient Automobile The pursuit of producing a more fuel-efficient automobile does not rely solely on the efficiency of the engine. A great amount of fuel efficiency gains are possible not because of improvements to engine design but because of improvements in materials....

Read

Topics: