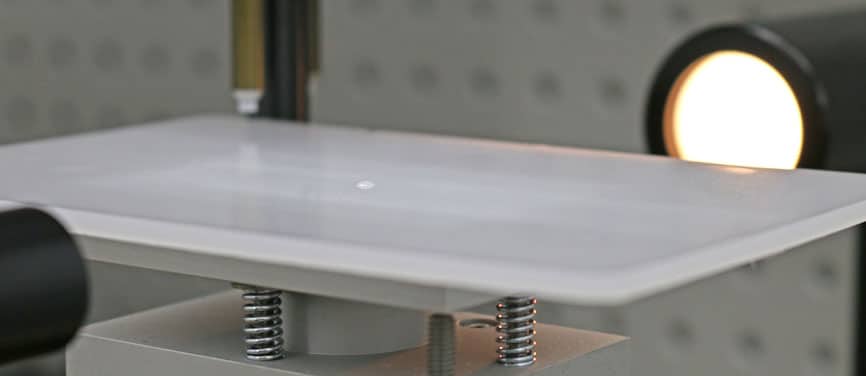

Manufacturers are familiar with adhesion challenges when attempting to bond, paint, etch, or coat a substrate. Poorly prepared surfaces can undoubtedly produce problematic adhesion issues.

A common standard for measuring the effectiveness of paint adhesion relies on an archaic method: The Tape Test. While the Tape Test can provide some insight into adhesive ability, its analysis is subjective, the process is time-consuming, and it is a destructive test. There are also many conditions that are difficult to control and maintain consistency. For instance, the force at which the tape is peeled, the speed at which the tape is peeled from the surface, as well as the pressure at which the crosshatch grid is applied all contribute to the tests' downfalls.

A common standard for measuring the effectiveness of paint adhesion relies on an archaic method: The Tape Test. While the Tape Test can provide some insight into adhesive ability, its analysis is subjective, the process is time-consuming, and it is a destructive test. There are also many conditions that are difficult to control and maintain consistency. For instance, the force at which the tape is peeled, the speed at which the tape is peeled from the surface, as well as the pressure at which the crosshatch grid is applied all contribute to the tests' downfalls.

Furthermore, it can only be done post-treatment and application or in the lab for research and development. So, this test is not practical or possible to use as a surface readiness indicator prior to bonding on the manufacturing floor. Contact angle measurements are a more reliable, objective, simple, fast, and non-destructive way of measuring how prepared a surface is for perfect adhesion.

Download the paper: Water Contact Angle Correlation to Crosshatch Adhesion Tape Test in Accordance with ASTM D3359-09