Industries

Aerospace

Solve Complex Adhesion Problems in Aerospace Manufacturing

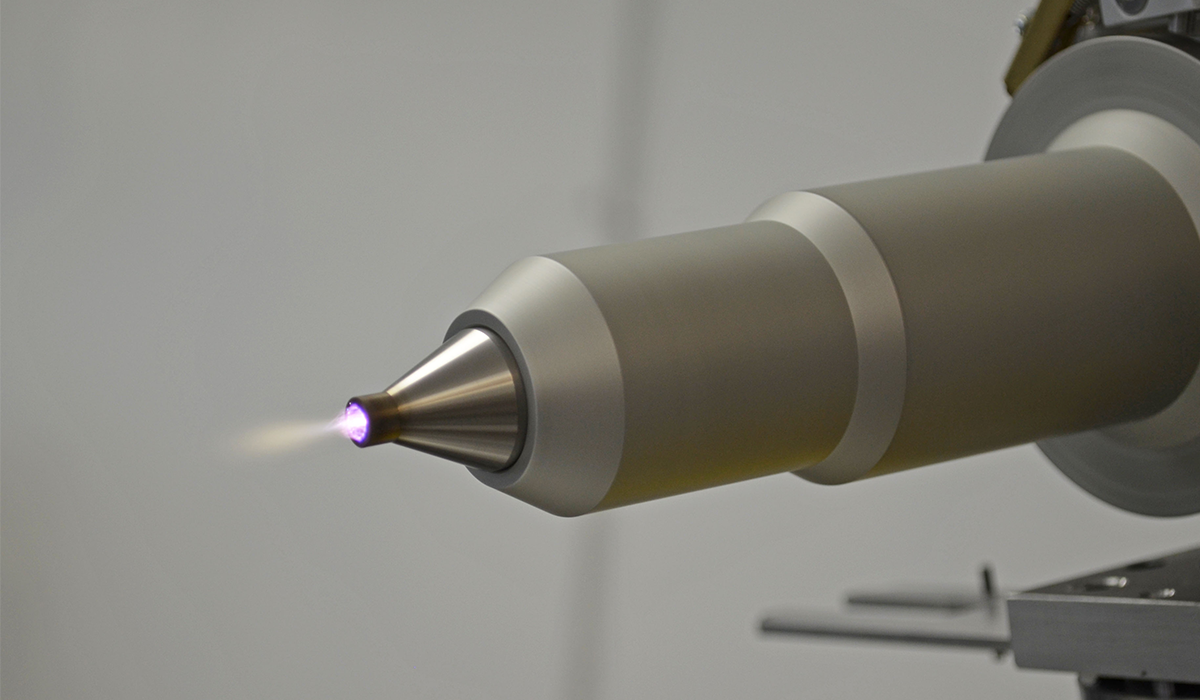

Born from the F-35 Joint Strike Fighter program, the Surface Analyst first spread its wings in the aerospace industry. With 25 years of experience solving the most complex adhesion problems, we’re showing the world’s top companies just how simple it is to bring total surface quality control to the manufacturing floor to build reliable aircraft.

Common Aerospace Applications

- Replace water break testing

- Guarantee adhesion of bonded fasteners, studs & brackets

- Validate coatings on aircraft electronics and cabling

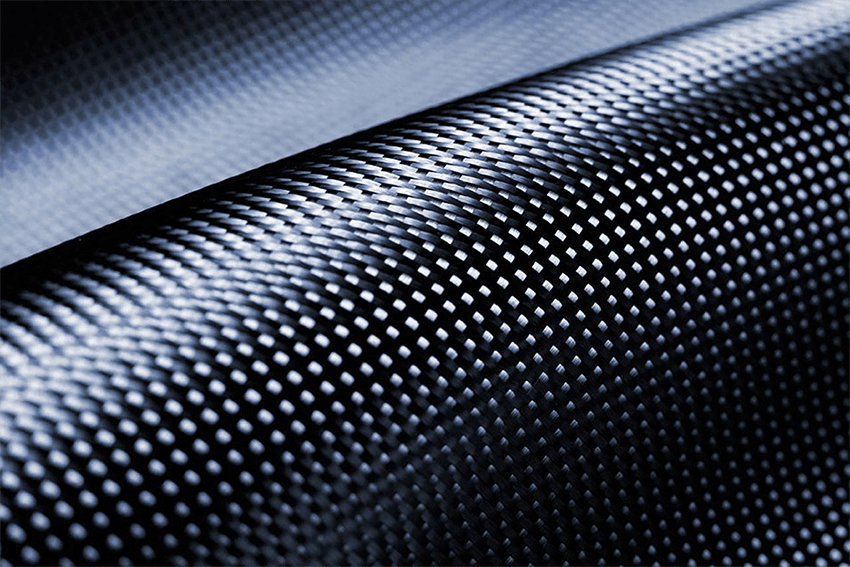

- Achieve optimal surface preparation in composite and metal bonding and repair

- Develop surface cleanliness specifications for painting and priming

- Quantify the exact amount of abrasion required for successful structural bonds

- Establish a quantifiable surface specification for materials from suppliers

- Continually monitor manual surface preparation processes like solvent cleaning

- Understand the effects of aging and storage on material quality

- Detect peel ply on composite surfaces

Our Customers

.png?width=177&height=131&name=lockhead-martin-aerospace-transparent-logo%20(177x131).png)

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.