When manufacturers experience difficulties relating to product quality, it's common to believe the issue to be internal, and this is sometimes the case.

But what happens when product quality issues during manufacturing stem from outside the operation itself?

Incoming materials are often an undiagnosed cause of difficulties related to product quality, and until a reliable method is discovered and implemented to create and verify supplier standards, problems will continue to occur.

A recent customer, a manufacturer of solar panels, discovered an unexpected issue with their incoming material quality, and the Surface Analyst was able to shine a ray of light on this dark corner.

The Material & Process

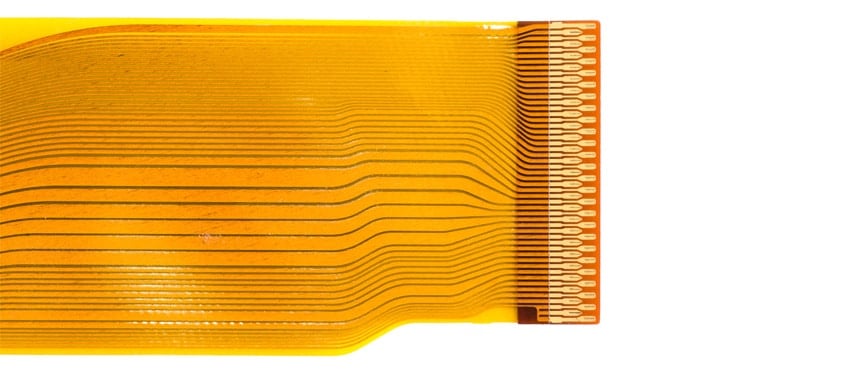

A major component of the interior assembly of their solar panels is a plastic polymer, Nylon 66. This plastic must be bonded to a portion of the solar cells in such a way that the bond can withstand environmental stresses for at least twenty years.

This bond is paramount to offering a long-lasting and high-quality product to the final customer.

Thus, the surfaces of these polymers must be properly prepared to hold a resilient bond. The company necessitates that their suppliers do not use any mold release when producing their plastic polymer components. Mold release contains silicone, a very low-energy material that will prevent a bond from succeeding.

The Problem

The company began to experience bonding failures inconsistently and was unable to identify why these failures were happening.

The solar panel manufacturer used the Surface Analyst™ with the guidance of the lab and sales team to scrutinize the surface of their plastic polymers.

The Measurement

The company was able to determine that an acceptable contact angle measurement for this surface to promote proper adhesion is approximately 60°.

Conversely, some of their surfaces were reading angles in the high eighties and low nineties. This was an indication of a low-energy contaminant such as silicone.

This was proof that the material had not been prepared according to specification, and the source of the problem was able to be identified.

The Solution

Using the data obtained with the Surface Analyst, the solar panel manufacturer now had concrete figures to take to their supplier that succinctly demonstrated product quality.

The science behind the measurement provided certainty, clarity, and direction; that was the final answer the company had been looking for.

The solar panel manufacturer gained the ability to verify the presence of a silicone contaminant on the surface with non-subjective, quantifiable data.

The Result

The manufacturer could communicate clearly with the supplier to ensure their needs were met. This meant requiring the manufacturer to verify that their product is properly constructed prior to shipping, meaning the company saved money, time, and energy lost to shipped product that proved to be unacceptable.

On the manufacturer's end, the amount of rework, downtime, and the resulting frustrations essentially disappeared as a new benchmark was set for which the company could effectively operate.

Thus, all companies were on the same page, and in the end, the solar panel manufacturer gained the ability to confidently verify incoming products.

Optimize the power of next-gen connectivity with data & surface intelligence.