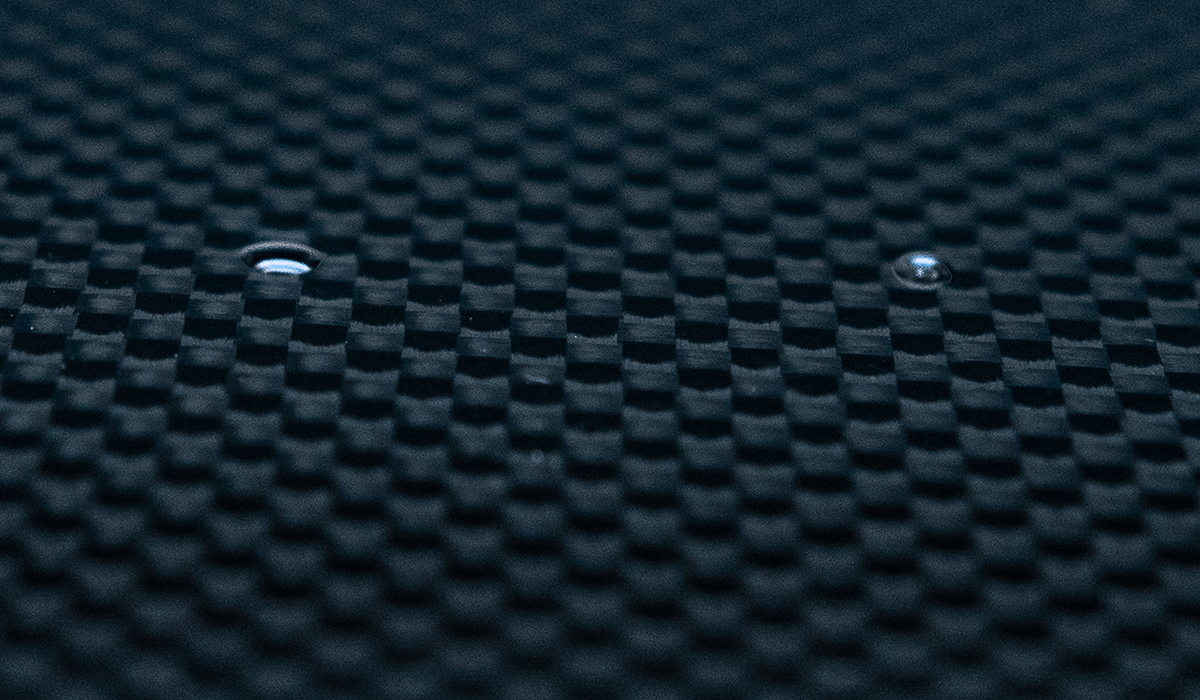

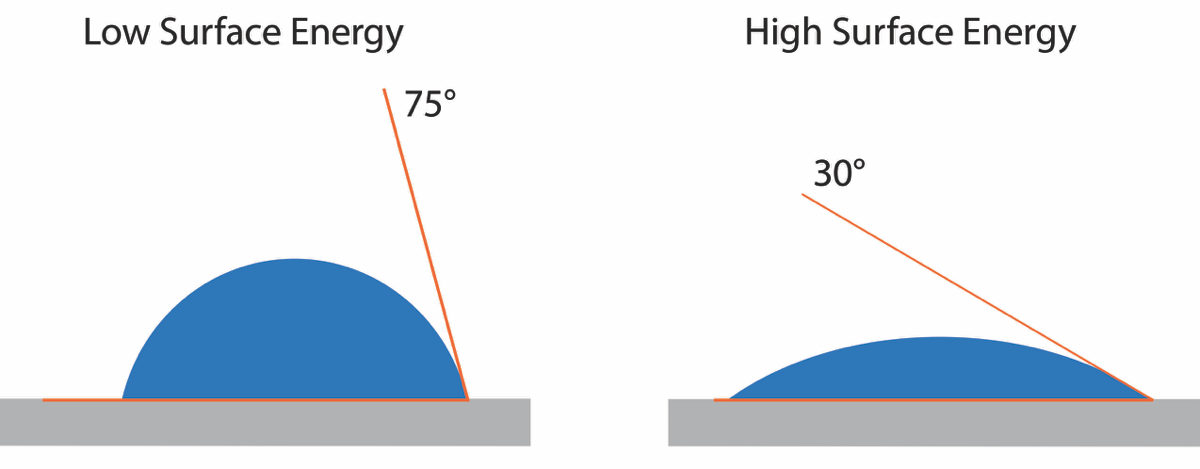

When measuring and quantifying surface energy, a common question arises: "Does surface roughness impact contact angle measurements obtained by the Surface Analyst?" In response, Surface Intelligence experts at Brighton Science launched a research project to determine whether contact angle measurements obtained by the Surface Analyst™ are impacted by surface roughness. The study examined the effect—or lack thereof—that roughness has on contact angle measurements.

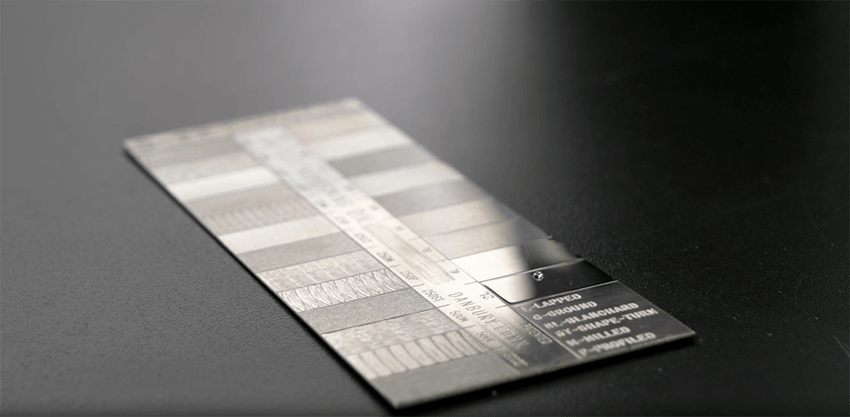

To conduct the study, Brighton Science scientists used a Surface Finish Comparator—a nickel plate containing 21 panels of varying roughness and texture is representative of surfaces typically encountered in manufacturing processes.

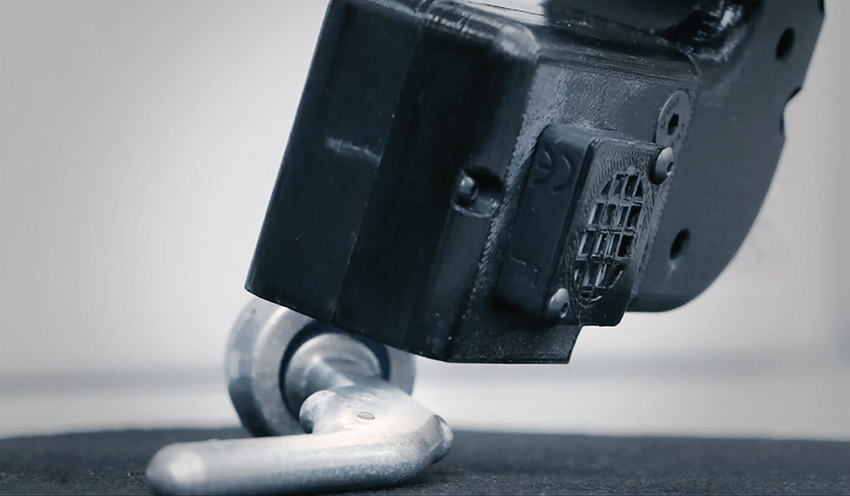

Watch how the Surface Analyst measures contact angle on surfaces with varying finishes.

Want to dig deeper? Read the full paper to see how the Surface Analyst has been designed to measure contact angle on real-world surfaces.

Rethink your adhesion manufacturing processes with Surface Intelligence.

To learn how you can leverage surface analysis data to proactively control adhesion processes in new product development or use it to find the root cause of failure within production, download the eBook and checklist, "Adhesion Failure Root-Cause Analysis for Manufacturers."