Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

Posts by Topic

Corona Treatment Concerns You Need to Take a Closer Look At

Disclaimer: This article is NOT about COVID-19; it is about a surface treatment process for better surface preparation and adhesion properties in manufacturing. If you're looking for information about cleaning, here's an article that discusses the difference between biological cleanliness and...

Read

Topics:

Is Inconsistent Surface Preparation Hurting Your Bottom Line? Here's the Fix.

In manufacturing, consistent and high-quality products are paramount to success. Surface preparation is critical in ensuring product performance, appearance, and durability. However, variations in surface preparation processes across an enterprise can lead to inconsistencies, inefficiencies, and...

Read

Topics:

What is Surface Treatment? A Comprehensive Guide to Surface Treatment Methods for Manufacturers

In the world of manufacturing, surface treatment plays a crucial role in achieving high-performance adhesion. Whether bonding, coating, sealing, painting, or printing, every manufacturer understands the significance of a well-defined adhesion process. Think of adhesion as the glue that holds a...

Read

Topics:

Unlock the Key to Successful Adhesive Bonding: What You Need to Know Beyond Adhesive Technical Data Sheets

Manufacturers are increasingly utilizing a greater number of adhesive materials as a joining technique in the construction of their products, and the importance of these uses is continuously increasing with each passing year. As a result, the consequences of adhesive bond failures are becoming more...

Read

Topics:

Silicone Contamination: The Invisible Intruder to Quality in Assembly Line Production

Some manufacturers go to extraordinary lengths to eliminate the presence of silicone in their manufacturing facilities. Some manufacturers invest significant resources in cleaning procedures to eradicate any silicone contamination. These approaches can be revolutionized by the development of a...

Read

Topics:

How to Propel Enterprise Success through Effective Knowledge Sharing of Bonding Processes

Wind turbines have a problem: their giant blades fail more often than anticipated. Research on the issue, reported in the journal Materials, notes an average of 3,800 failures each year. Many of these result from adhesive bonding defects, which should be addressed and prevented through improved...

Read

Topics:

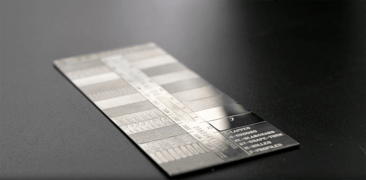

Maximize Manufacturing Excellence: Harness the Potential of Surface Quality Verification and Certification

In manufacturing, surfaces hold immense significance, and their value can be traced back to the inception of the Federal Aviation Administration (FAA) during the 20th century. The establishment of the FAA emerged as a response to mounting concerns surrounding quality control and the occurrence of...

Read

Topics:

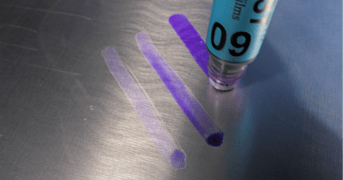

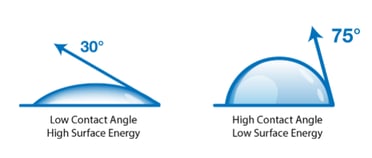

Demystifying Dyne Levels: A Comprehensive Guide

The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability....

Read

Topics:

Discover the Top Alternative to Dyne Testing That Gets Results

Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind...

Read

Topics:

Surface Analyst Technology Replaces the Old Language of Dyne Ink

For over a decade, manufacturers and suppliers have spoken the language of dyne when dealing with surface preparation and treatment verification. Because the process of dyne analysis requires users to interpret the way the ink spreads on a surface, it is highly subjective, making the language of...

Read

Topics:

Guess the Contact Angle: IPA Wiped Composite Material

This 'Guess the Contact Angle' video is the first of our next series of videos focusing on how contact angle changes when a composite surface is cleaned or treated in various ways. The contact angle featured in this demo is formed by a water droplet deposited using the handheld Surface Analyst on...

Read

Topics:

Why a Surface Chemistry Input Should be Included in New Product Specifications

When development teams are looking to build a new product that includes a coating, bonding, painting, or sealing process, it's only natural to consider what kind of adhesive, coating, or paint will perform the best. While these selections are critical to the end product's success, development teams...

Read

Topics:

How Surface Quality Can Negatively Impact Product Launches

Manufacturing is a team effort. And as such, when an issue arises with the product (usually caught when scrap rates skyrocket and returns, recalls, and warranty claims make it clear something was missed), it can be difficult to precisely isolate the root cause of the problem.The interconnectedness...

Read

Topics:

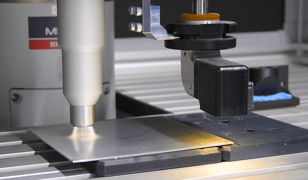

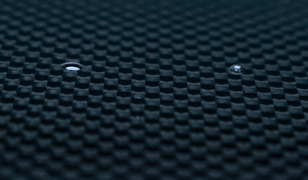

Does Surface Roughness Impact Contact Angle Measurements?

When measuring and quantifying surface energy, a common question arises: "Does surface roughness impact contact angle measurements obtained by the Surface Analyst?" In response, Surface Intelligence experts at Brighton Science launched a research project to determine whether contact angle...

Read

Topics:

How to Measure Contact Angle on Convex and Concave Surfaces

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with abenchtop goniometer. The challenges arise from the way goniometers measurecontact angle—from a...

Read

Topics:

Guess the Contact Angle: Plasma Treated Aluminum

So far in our Guess the Contact Angle Series, we have brought you three videos demonstrating how contact angle changes depending on the state of the material surface: Contact angle measurement on a piece of aged, 'as is' aluminum Contact angle measurement on aluminum after cleaning it with an IPA...

Read

Topics:

The Benefits of Benchmarking Surface Quality in Manufacturing

Certainty is the goal of every manufacturing process. Manufacturers need to have total confidence that every aspect of their production process will go according to plan. The adhesion process needs to be controlled just like any other production operation, with accuracy and ongoing monitoring....

Read

Topics:

How to Conceptualize and Design Products Using New Materials and Substrates with Confidence

Materials as technology is one of the most important fields in developmental science. As new materials are created and perfected, they proliferate and quickly spread to manufacturing centers around the world, spurring innovative product design. The rapid development of ceramic, sustainable...

Read

Topics:

Why Automotive Glass Bonding Recalls Should be a Thing of the Past

Automotive glass is a technological marvel. Despite its clarity, there is a lot that is unseen by the average driver. Silica compounds, tempering, and lamination all combine to create one of the most critical components of today’s motor vehicles. Unfortunately, though, things periodically go wrong...

Read

Topics:

Guess the Contact Angle: Abraded Aluminum

So far, in our Guess the Contact Angle Series, we have brought you two videos: the first one shows the Surface Analyst taking a contact angle measurement on a piece of aged, 'as is' aluminum. The second video asks you to guess the contact angle after we took the same piece of aluminum but cleaned...

Read

Topics:

Guess the Contact Angle: IPA Wiped Aluminum

As part of the Guess the Contact Angle series, we have brought you a new video that highlights best practices when cleaning material surfaces with IPA wipes and we will ask you to "guess" the contact angle measurement after the surface has been cleaned. The contact angle featured in this demo is...

Read

Topics:

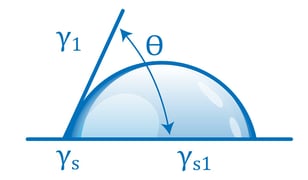

Leveraging the Variability in Contact Angle Measurements to Improve Surface Quality and Process Control

Determining whether your material surface has been adequately cleaned or prepared for bonding, coating, sealing, painting, or printing requires the ability to objectively quantify the chemical and physical characteristics of the top few molecular layers: this is where all the action is. Water...

Read

Topics:

Can Contact Angle Quantitatively Measure Total Surface Energy?

In an article published in the Journal of Adhesion Science and Technology, "Water Contact Angle as a Quantitative Measure of Total Polyethylene Surface Energy" Materials Scientists from Brighton Science (formerly BTG Labs) explain the validity of water contact angle as a measurement for total ...

Read

Topics:

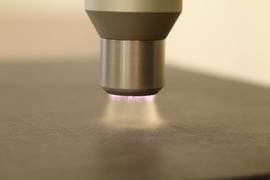

How Manufacturers Can Optimize the Effectiveness of Plasma Activation

In last week’s blog post, Using Plasma for Surface Cleaning and Activation, Rose Roberts, Ph.D., Brighton Science's (formerly BTG Labs) Senior Custom Applications and Materials Engineer, discussed how to use plasma for the dual purposes of cleaning critical surfaces and activating critical surfaces...

Read

Topics:

Using Plasma for Surface Cleaning and Activation

This blog post is the first of a two-part series focusing on plasma. With the help of Rose Roberts, Ph.D., Senior Custom Applications and Materials Engineer, we will review plasma basics and discuss how plasma can be used for both cleaning and surface activation. We will also touch upon the...

Read

Topics:

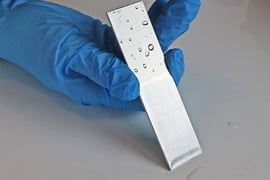

Quantifying the Effectiveness of High Volume Metal Cleaning in Fresh and Aged Baths

In today’s video, we will show you how to quantify the surface quality of metals when using fresh and aged baths. We will demonstrate how Water Contact Angle (WCA) measurements can provide feedback in less than two seconds on the effectiveness of your cleaning process and will enable you to improve...

Read

Topics:

Guess the Contact Angle: Aged 'as is' Aluminum

In today’s blog post, we are going to have a bit of fun using video to learn more about contact angles. We will show you a contact angle and will ask you to “guess” the contact angle measurement. The contact angle featured in this demo is formed by a water droplet deposited on a piece of ‘as is’...

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

In recent articles, we’ve discussed what surface tension and surface energy are. Manufacturers need to acquaint themselves with these concepts because controlling surface quality through surface energy measurement of solid materials is the most predictive method of ensuring high-performance bonds...

Read

Topics:

What is the Difference Between Surface Free Energy and Surface Energy?

When it comes down to it, this is another purely semantic question, much like the one we dealt with in another article comparing the terms “surface tension” and “surface energy.” Surface-free energy is free energy in a particular space - the surfaces of materials. Free energy, in its most...

Read

Topics:

How to Measure Surface Tension

The attractive force of the molecules present at the surface of a liquid towards each other is called the surface tension of that liquid. It may seem like a little thing (and in terms of mass, it doesn’t really get much smaller than the top few molecular layers that make up the surface of a liquid...

Read

Topics:

What is the Difference Between Surface Tension and Surface Energy

Using adhesives in manufacturing is becoming increasingly common for building everything from massive machines to everyday tech devices. But companies' reliance on the science of adhesion to make sure their products work perfectly and look marvelous didn’t start there. In the centuries since the...

Read

Topics:

Manufacturing Best Practices for Business Continuity Plans

Even though coming to the end of 2020 has not at all meant the end of the impact of Covid-19, manufacturers are pushing forward to make sure 2021 is not marred by the setbacks of this year. This has not been a normal economic downturn, and the ways to remain resilient in the past are not enough to...

Read

Topics:

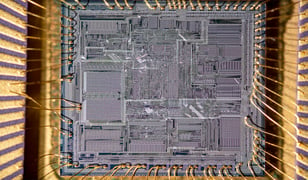

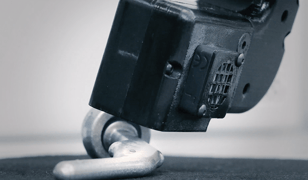

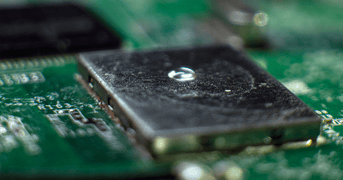

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

What Medical Device Manufacturers Need From Surface Cleanliness Testing

Quality tests during medical device production need to check a lot of boxes for manufacturers. Testing must increase confidence in product reliability in order to be worthwhile to manufacturers. What’s more, that confidence needs to be measurable and reportable because companies cannot tolerate...

Read

Topics:

A Great Idea to Help Save the Aerospace Industry

2020 is a year that will live in infamy for many industries. We haven't even seen the full effect of Covid-19 on economies, which inserts a heap of uncertainty into decision-making for manufacturers. But one thing is for sure: we're not going to get back to business as usual anytime soon. The ...

Read

Topics:

Everything Breaks: What Reliability Means for Adhesively Bonded Products

The seemingly easy and obvious answer to the question implied in the title of this article is: reliability means no failures whatsoever forever and ever, amen. Sadly, it’s not quite so simple.

Read

Topics:

The Huge Need for Zero Defect, Large Scale Molding Processes

Manufacturing large-scale molded products such as pools, boats, and aircraft parts is as herculean a process as the products they generate. Colossal molds are used to form fiberglass and other composites into aircraft wing panels, fuselages, boat hulls, bus shells, and pools.

Read

Topics:

Process Control Innovations for Card Manufacturers

We’ve all experienced the disappointing (and kinda embarrassing) moment when we’re at a register trying to buy armfuls of tortilla chips and salsa, and the point-of-sale card reader screams out that an error has occurred.

Read

Topics:

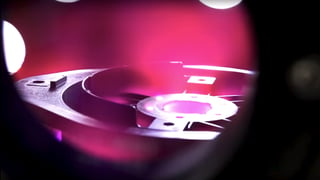

The Best Method of Controlling HMDS Use in Semiconductor Manufacturing

Semiconductors are one of the most fascinating areas of electronics manufacturing. The ability to “grow” almost irreducibly small integrated circuit components on silicon wafers has made an incredible amount of micronization possible. The theory has always been that as the chips got smaller, their...

Read

Topics:

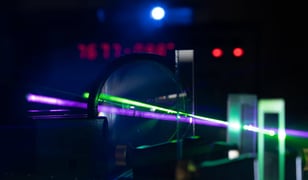

Surface Preparation for Reliable Optical Coatings in Photonics Manufacturing

Coatings are an indispensable part of manufacturing photonics. The coatings help determine the most basic functionality of the lenses they are applied to. How much light passes through, what happens to that light when it passes through the lens, does some light get absorbed, and are some spectral...

Read

Topics:

Ensuring the Durability of Oleophobic Coatings on Consumer Tech

We’re all thinking a lot more about the surfaces we touch and the invisible things that might be on those surfaces. Manufacturers have been thinking about how surfaces interact with our skin and the environment long before COVID-19 made us all much more cognizant of what we can get from touching...

Read

Topics:

3 Things You Need to Know to Create Strong, Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, more reliable, and in the automotive and aerospace sectors, lightweight products. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys that have a lower density, better temperature tolerance, and...

Read

Topics:

How to Know if Hydrophilic Coatings on Medical Devices Provide the Necessary Comfort for Patients

Comfort is more than just a nice thing to hope for when it comes to medical devices like tubing, catheters and stents that are implanted into the human body. Comfort, in this instance, refers to the absence of pain. Having a piece of plastic or metal inserted into your body is never going to feel...

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 2: Why one fluid is all you need for process control in manufacturing

This is part two of a two-part series explaining Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical paper written by Dr....

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 1: Surface energy and the attractions between substances

This is part one of a two-part series explaining the finer points of Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical...

Read

Topics:

Will New Hand Washing Practices Cause Problems for Manufacturing?

Like many industries during the COVID-19 crisis, manufacturing has had to make big changes, including scaling back its workforce, enforcing new and intensified hygiene standards, and taking a closer look at workplace cleanliness. Looking ahead to the permanent adjustments we’re all making, it’s...

Read

Topics:

Study Proves the Surface Analyst is Dependable for Process Control

One of our favorite services we provide to manufacturers is to help optimize surface preparation techniques for their particular materials and products. It’s our specialty and one of our biggest passions. We feel so strongly about it because we know that if you, as a manufacturer, are able to...

Read

Topics:

How to Get the Most Out of Your Vacuum Plasma Treatment

Vacuum plasma is the treatment method of record for many manufacturers. Not only because it is a legacy technology proven useful over many, many decades but because it can be particularly effective at creating chemically reactive surfaces of various geometries that need to be bonded, coated,...

Read

Topics:

How to Bond PTFE to Anything

Polytetrafluoroethylene, or PTFE, is a very common material widely used in almost every major industry. This ultra-lubricious and multi-use fluoropolymer touches everyone from the aerospace and automotive industries (as an insulating cover on cabling) to musical instrument maintenance (it’s found...

Read

Topics:

Plasma Treatment for Complete and Reliable Cleaning with Richard Burke

At IPC APEX 2020 in San Diego, we wanted to explore the ways that electronics manufacturers, who encapsulate their circuit boards with a conformal coating, are cleaning their boards. What are the benefits to their current processes, and what are some things manufacturers could learn to make their...

Read

Topics:

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. For aircraft OEMs, one of the most crucial aesthetic operations is the topcoat of paint, although...

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Formed In Place Gasket (FIPG) Reliability Starts with the Surface

Form-in-place-gaskets (FIPG) have been a revolutionary advancement in industries that bank on high-reliability sealing applications. FIPG is a versatile sealing technique that deploys a mostly silicone (they can sometimes be blended with metals like silver, aluminum, and nickel for conductivity...

Read

Topics:

Surface Preparation for Primer Coating of Composites in Aerospace Applications

A lot goes into painting an aircraft. This massive, multi-stage process begins long before that final, shiny topcoat you see on the wings and tail is applied. The components are molded, then they’re prepared (which is often a multi-step process in-and-of-itself), then they’re assembled, then there...

Read

Topics:

Conformal Coating Failure Caused by Poor Surface Cleanliness

Electronic components consist of many exposed and delicate pieces that leave them vulnerable. A lot is relying on these fragile parts to function without fail. From implantable medical devices to navigational equipment and from sensor packages in cars to cell phones, the manufacturers of electronic...

Read

Topics:

Is Roughness as Important as Surface Cleanliness to Adhesion?

When the subject of material surfaces comes up among manufacturing engineers, the discussion usually centers on the physical attributes of that surface, the surface topography or morphology, or more simply - the surface roughness. Preparing material surfaces for assembly, coating, painting, or...

Read

Topics:

Surface Treatment of Thermoplastics for Aerospace Components

The Aerospace and Defense Industry is experiencing a market boom right now. Investments in the aerospace industry are an increasingly significant part of the world economy. Last year, almost $1 trillion was spent worldwide, with about $400 billion spent directly on aircraft and space systems...

Read

Topics:

The Tools & Skills to Address Adhesion Problems in Production

When adhesion issues become apparent in a manufacturing process, they can seem to come out of nowhere. When coatings on circuit boards delaminate and cause shorts, when automotive glass doesn’t properly seal and moisture is let through, or when implantable medical devices aren’t meeting cleanliness...

Read

Topics:

Best-practice Surface Preparation Processes for New Products

New Product Development is an essential component to the successful growth of companies that always challenge themselves to improve and innovate. Getting this design stage right is pivotal in that it sets in motion everything the product will be and how well it will perform.

Read

Topics:

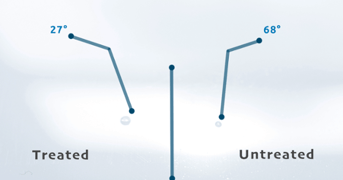

How to Know if a Manufacturing Surface is Treated or Untreated

In order to ensure successful bonding, coating, printing, painting, laminating or meet cleanliness standards in manufacturing, material surfaces must be manipulated. One such manipulation that gets surfaces ever closer to being ready for adhesion is surface treatment. There are many operations and...

Read

Topics:

How to Transfer a Lab Surface Treatment Process to Production

Production processes don’t just materialize fully formed on the manufacturing floor. Procedures and operations go through a full research and development cycle, which can take years before they are integrated into the production line. This pre-production work includes strength, reliability, and...

Read

Topics:

Why a Surface Quality Inspection Process Ensures Adhesion

Manufacturing processes that involve bonding, coating, sealing, printing, painting, laminating, or cleaning need a metric to measure the surface quality of the materials involved. Without such a metric, it is impossible to predict whether the adhesion process will be successful or if it's on the...

Read

Topics:

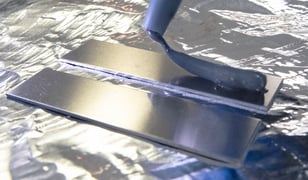

New and Better Surface Quality Test Than the Water Break

There are times when trying to discern if adhesion in manufacturing will succeed seems like a deeply mysterious and opaque puzzle. The water break test is a simple and fairly straightforward method of detecting hydrophobic (water-repellant) contaminants on surfaces, most commonly on flat sheets of...

Read

Topics:

How to Fix Common Causes of Adhesion Problems

Manufacturers often have a large blind spot when it comes to the causes of adhesion problems. This blind spot makes it impossible to solve these problems and generates frustration and loss rather than productivity and adhesion success. Taking the blinders off and taking on adhesion failure at its...

Read

Topics:

10 Most Common Surface Quality Mistakes by Manufacturers

Manufacturers are constantly fighting against adhesion problems. Surfaces not sticking and adhesives not working is the daily reality facing manufacturers looking to make high-quality, reliable products. The daunting nature of the task of eliminating adhesion failure seems insurmountable and...

Read

Topics:

Deck the Hulls: Preparing Ship Hulls for Coating and Painting

Manufacturing a product to withstand the environmental stresses of wind, rain, and sediment is challenging enough. But, when you add saltwater and wave action to the mix, the detrimental threat of corrosion increases significantly. A coating adhesion test is important for quickly testing a surface...

Read

Topics:

Tales from Brighton Science's Materials & Processing Lab

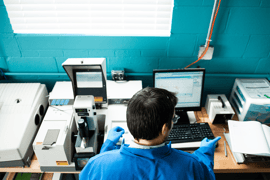

In the Brighton Science Materials and Processing Laboratory, magic happens. Or, at least, it seems that way. In the lab, our specialists see the unseen. They use expertise, specialized tools, and data to reveal the invisible.

Read

Topics:

Surface Treatment Processes: Flame Treatment

Flame treatment is a surface activation treatment process used to chemically modify a surface for better adhesion. This process is typically used on low-energy surfaces that can be difficult to adhere to, such as plastics and composites. The treatment is also very gentle, posing low risk to the...

Read

Topics:

CMH-17 Composite Materials Handbook: Validating Surface Preparation

Ongoing Advancements in the Field of Composite Materials Brighton Science (formerly BTG Labs) maintains an important connection to CMH-17, the Composite Materials Handbook. Brighton Science's special connection began in 2004 when Giles Dillingham, Founder and Chief Scientist, read that CMH-17...

Read

Topics:

Automotive Series: Surface Preparation of Composite Surfaces

Building a More Fuel-Efficient Automobile The pursuit of producing a more fuel-efficient automobile does not rely solely on the efficiency of the engine. A great amount of fuel efficiency gains are possible not because of improvements to engine design but because of improvements in materials....

Read

Topics:

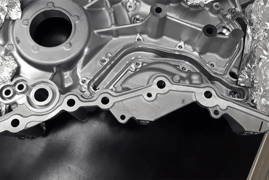

Contact Angle Analysis: Sealing Surface of Aluminum Castings

Surface Quality Requirements of Aluminum Castings Automotive manufacturers widely utilize aluminum castings as the most successful way to create aluminum parts. However, this process can involve inorganic contaminants on the surface, which interfere with potential bonding, sealing, or coating....

Read

Topics:

Automotive Applications Series: Evaluating Surface Preparation for the Automotive Industry

Automotive manufacturers who bond, seal, coat, paint, or print now have a reliable way to verify the cleanliness of their surfaces.

Read

Topics:

Contact Angle Measurements on Oxidized Polymer Surfaces Containing Water-Soluble Species

When Polymer Surfaces are Not Easily Accessible A collaboration between Brighton Science (formerly BTG Labs) and 3M scientists demonstrates that the Surface Analyst™ can provide receding contact angles. These contact angles precisely match the Wilhelmy-balance values, but in seconds instead of...

Read

Topics: