Updated March 2023

Dyne inks and dyne pens are still the industry normal for companies around the world, but its users commonly report pitfalls such as excess waste from the ink destroying their products and a lack of control over continuous improvement as a result.

How is Dyne Ink Used?

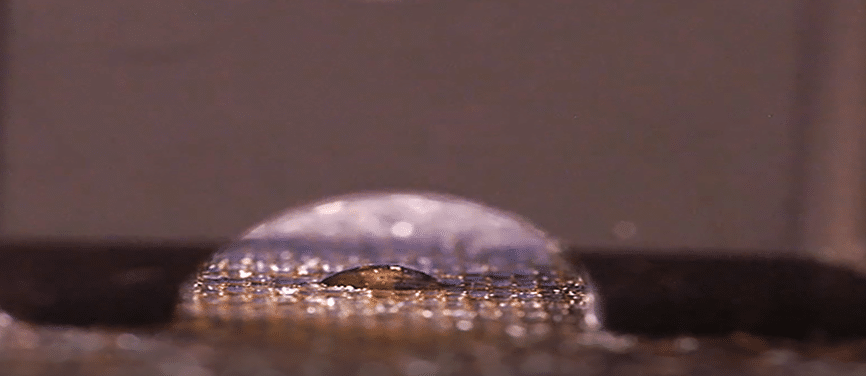

Dyne inks (whether applied with cotton swabs or by using a dyne pen) provide an estimate of surface energy. What they actually measure is a property called wetting tension or the surface tension of a liquid that will just wet the surface (i.e., not bead up) under a carefully specified set of application conditions. The surface tension of this liquid is related to the surface energy of the substrate.

While suitable in some cases for estimating surface energy (and therefore cleanliness or treatment level), the imprecision and subjectivity of wetting tension measurements make them a poor choice for quality assurance and process control of surface cleaning, surface treatment, bonding, coating, adhesion, and printing operations.

A Nightmare for Regulators and Employers

Dyne inks are typically a mix of two or more solvents, making them an occasional source of VOCs or “volatile organic chemicals.” VOCs are known to be destructive to the environment and harmful to the people who use them. Some mixtures are simply water and alcohol, but others have either non-zero toxicity or extremely high levels of toxicity to human beings.

An ACCU dyne test that uses fluids to test the surface tension of a material was tested and reported in a Safety Data Sheet (SDS) (revised at the end of 2022), and one related chemical was found to be hazardous, “2-ethoxyethanol and Methyl Violet 28 are considered hazardous by the 2012 OSHA Standard (29 CFR 1910.1200).” Based on the California Proposition 65 law, “2-ethoxyethanol is known to the State of California to cause birth defects or other reproductive harm.” The European Chemicals Agency also calls out similar reproductive toxicity exhibited by that chemical in particular. So not only are certain dyne inks destructive, but they are also considered toxic to the people using them.

Rethink your adhesion manufacturing processes with Surface Intelligence.

The Surface Analyst: A Sustainable, Non-Toxic, and More Accurate Test for Surface Energy

In comparison, the Surface Analyst™ uses high-purity water, which eliminates any toxicity factors dyne ink may bring to your production line. For people working the frontlines and creating the products we use daily, avoiding toxic chemicals is just one criterion to have a safe work environment – something all businesses should prioritize.

Both our handheld and automated systems are safe alternatives to dyne ink or dyne pens that gauge surface condition and consistency by rapid, automated measurements of the water contact angle in a precise, controlled manner. This water contact angle directly correlates with the cleanliness and consistency of a surface.

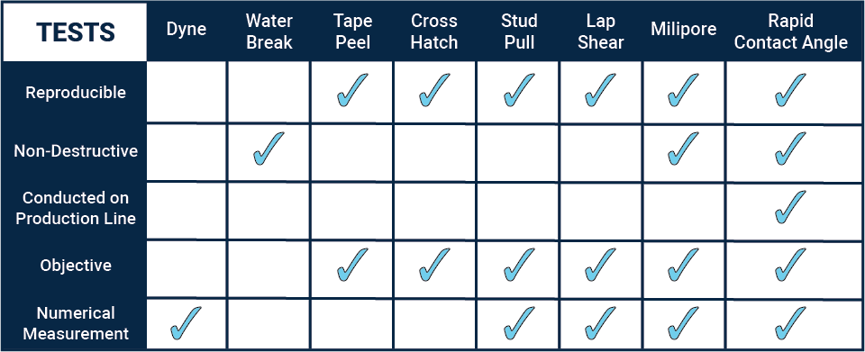

How Other Surface Energy Tests Measure Up

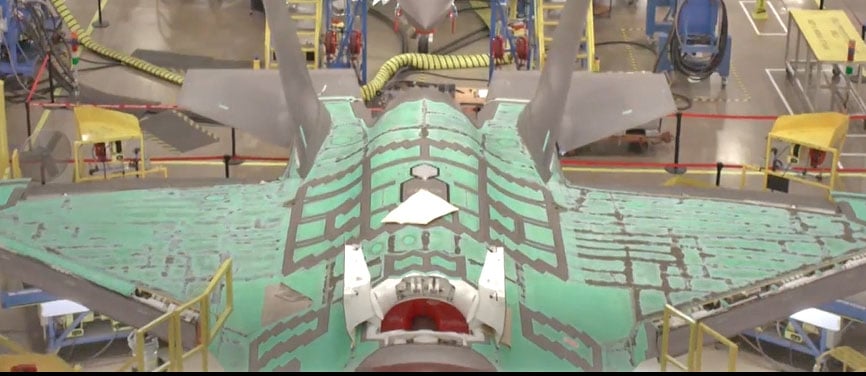

Not only is Dyne not reproducible or objective, but it's unable to be implemented on a large-scale production line. Water contact angle measurements, however, require little training to utilize and repeatable numerical measurements to supplement your testing.

Dyne inks are also destructive to the surface being measured – a major downside for the biomedical world, which relies on each object and material surface being able to be measured and then sent to the next step. Using rapid contact angle tests, you skip that destructive step, giving you a competitive advantage because you’re producing less scrap (saving you money) and wasting less time (saving you money twice over), which gives you more time to come up with your next innovative project.