Manufacturers who use solvent-based industrial parts cleaning processes must find alternative...

About

Our Story

Brighton Science, the global leader in surface intelligence.

The Brighton Science story

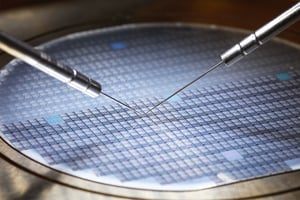

More than 20 years ago, Brighton Science began as a development lab for plasma polymerized coatings. Through research and development work led by Chief Scientist and Founder Dr. Giles Dillingham, Brighton Science made great strides in the field of material science and adhesives in manufacturing. It was during this time that Brighton Science developed the Surface Analyst, the first hand-held contact angle measurement device used in the development of adhesive bonding for the F-35 Joint Strike Fighter program.

As a solutions-focused company, Brighton Science has mastered the ability to ensure adhesion for manufacturers in an ever-growing array of industry applications. We’ve refined how research, design and production affect adhesion to help businesses create adhesion processes that result in quality products.

Through years of experience, our unparalleled products and our unique approach to fixing adhesion problems, we have helped some of the world’s largest companies build better products and develop reliable adhesion processes.

Join Our Team

We're always on the lookout for talented and motivated people who are as excited about innovation as we are. If this describes you, apply for a job to discuss your future with Brighton Science.

Brighton Science bases all hiring and employment decisions solely upon an individual's qualifications relating to the requirements of the position for which they are being considered, without regard to race, color, religion, sex, sexual orientation, marital status, national origin, age, handicap or disability. Veteran-welcoming. EOE.

Insights

Brighton Science is

the global leader

in surface intelligence.

Tell us your goals or challenges, and we can advise you on specific solutions you can put to work immediately or build into your optimization processes.

What could this mean for you?